PROPYLENE GLYCOL

Anti-Freeze | Freeze & Burst Protection

Non-Toxic | Non-Corrosive | Aluminum Safe

5 & 55 GALLONS

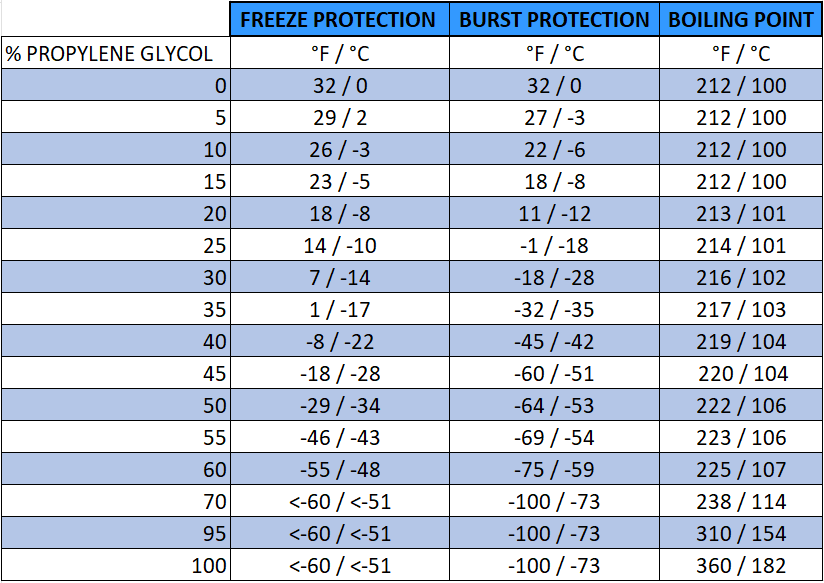

Mitco’s Propylene Glycol is non-corrosive and safe for closed systems where potable water exists. It is a heat transfer solution for use on hydronic, heat pump and solar heating systems. Product will not separate and leave deposits on heat transfer surfaces. Its lubricating qualities extend component life. Provides burst and freeze protection at temperatures as LOW as -100°F depending on PG% (see chart on bottom of page). All ingredients used are generally recognized as SAFE (GRAS).

REFERENCE:

PART # F5-5-60 (5 Gallon), F5-55-60 (55 Gallon) - 60%

PART # F5-5-95 (5 Gallon), F5-55-95 (55 Gallon) - 95%

OPTIONS:

- 5, 55, 275 gallon options

- CUSTOM COLORS & PERCENTAGES

- Custom Blends Typically Take 3-5 business days depending on the volume of the order. Custom orders require shipping zip code, color, percentage, quantity in gallons, and perferred container size of 5,55,275.

Email: sales@mitcomfg.com

GLYCOL CALCULATOR

SYSTEM VOLUME CALCULATOR

Inside Pipe Diameter:

Inches

Inches

Pipe Length:

Feet

Feet

Total System Volume =

CONCENTRATION ADJUSTMENT CALCULATOR

Volume of the System:

Gallons

Gallons

Current System Percentage:

%

%

Desired Percentage:

%

%

Gallons to be removed from system:

Gallons of water to be added to system:

Gallons of concentrate to be added to system:

NOTE: CONCENTRATION ADJUSTMENT CALCULATOR BASED ON 95% CONCENTRATION TO BE ADDED

Freeze & Burst Protection Chart